800.877.9510

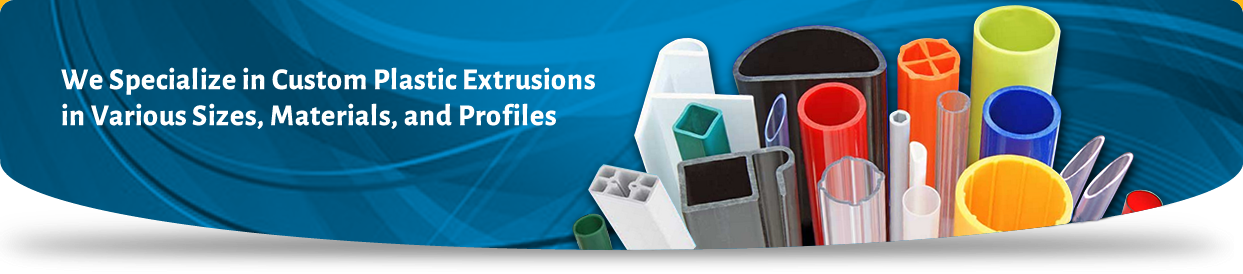

Thin-Wall Plastic Tubing

Genplex extrudes custom thin wall to meet your unique application requirements. Numerous features can be customized to your specifications. Our thin wall plastic tubing capabilities include:

- Sizes: We can extrude plastic tubing in sizes ranging from 0.025" to 5.0" O.D. (outside diameter).

- Clarity: We can provide water-clear, translucent, or opaque thin wall plastic tubing.

- Materials: Available materials range from ABS to polypropylene to HMW-HDPE (high molecular weight, high density polyethylene); select specialty materials are available upon request

- Durometer: Rigid, semi-rigid, and flexible thin wall plastic tubing is available

- Shapes: Round, oval, square, triangular, rectangular, hex, and custom profiles

Custom Thin Wall Plastic Tubing Formulations

We extrude thin wall plastic tubing in various grades and formulations to meet regulatory requirements for custom applications. We can provide FDA-grade plastic tubing, flame retardant grades to meet UL requirements, and thin wall plastic tubing with UV stabilizers for outdoor applications. Other special formulations are available upon request - contact us to discuss your custom requirements.

A range of value-add secondary services are also available to give you thin wall plastic tubing that is closer to or fully ready to use. We offer bending, notching, cutting, drilling, assembly, and more.

| PHYSICAL PROPERTIES | |||||||

| General Properties Range |

Density g/cc |

Tensile str.@ yield 1000 psi |

Elongation at yield % |

Flex. Mod 10E5 psi |

Notched Izod Impact |

Deflection Temp. F. |

UL 94 Rating |

| PET Polyester | 1.27 | 7.3 | 4%-4.3% | 2.9-3.6 | 1.7-1.9 | 153-158 | V-2 |

| High Impact Polystyrene |

1.05 | 2.7-4.3 | 5%-50% | 2.0-3.4 | .9-4.0 | 183-201 | HB |

| Polyvinyl Chloride Rigid |

1.4 | 5.3-8.0 | - | 2.5-4.3 | 1.0-23.0 | 150-170 | VO |

Thin Wall Plastic Tubing Applications

- Packaging of Crafts

- Toys

- Foods and Candy

- Medical

- Electronics

- Crafts

- and many, many more

Genplex: The Thin Wall Plastic Tubing Experts

Genplex has been extruding custom high quality, high precision plastic tubing since 1993. We are the full-service supplier you can trust. Request a quote on custom thin wall plastic tubing for your application, or contact us to learn more.